Production

Nonwovens

Cable Tapes

Services

NONWOVENS

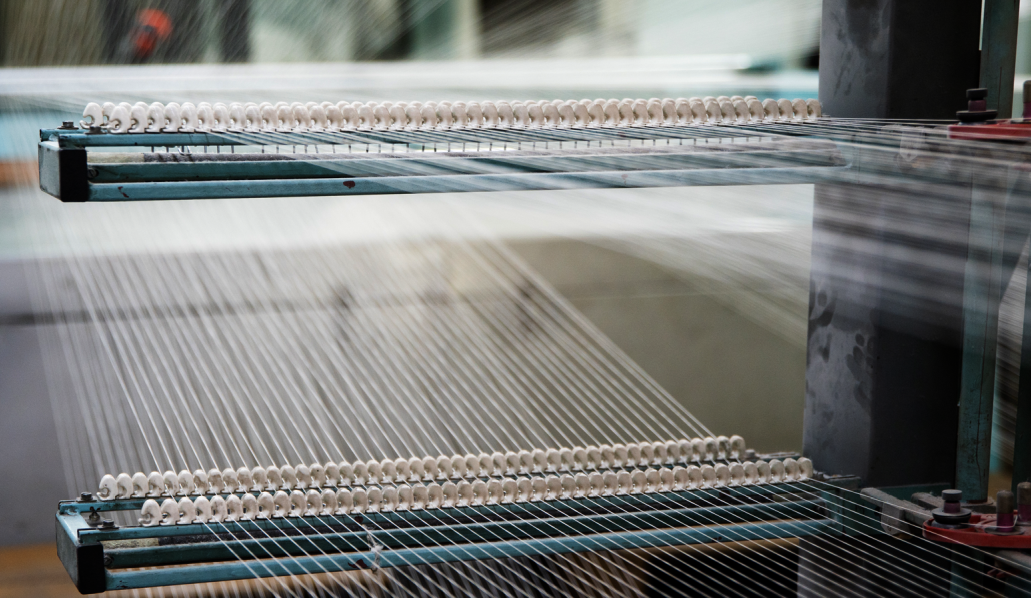

Filtration nonwovens are materials made from natural or synthetic fibres bonded mechanically, thermally or chemically to form a structure that enables effective retention of contaminants. Due to their unique structure, these nonwovens are widely used in numerous industrial sectors, including ventilation, air conditioning, environmental protection, medicine, the food industry and automotive applications.

They are manufactured from synthetic fibres, natural fibres or their blends, arranged to enable efficient separation of particles from liquids or gases.

Applications Of Nonwovens

Ventilation and air-conditioning systems (HVAC) – air purification from dust, particulates and other contaminants

Food industry – filtration of liquids such as fruit juices or beer

Medical sector – surgical masks, protective clothing, filtration processes (e.g. dialysis)

Automotive industry – air and fuel filtration

Environmental protection – wastewater treatment and emission reduction

Road construction – soil layer separation and drainage, especially in forest roads

Paint industry – absorption of paint mist

Protection of electronic equipment – protection of control cabinets and electronic devices from contamination

Types Of Filtration Nonwovens We Produce

Needle-punched Nonwovens (Mechanical)

- Applications: air and liquid filters, geotextiles, automotive filters

- Description: fibres mechanically bonded using barbed needles (polyester, polypropylene, polyamide, natural fibres)

Key properties:

- high mechanical strength

- flexibility and softness

- well-developed pore structure

- resistance to elevated temperatures (depending on fibre type)

Spunbond Nonwovens

- Applications: surgical masks, protective clothing, agriculture, automotive industry

- Description: fibres extruded from polymers (mainly polypropylene) and thermally bonded

Key properties:

- good tensile and tear strength

- low weight

- chemical resistance

- chemical resistance

Meltblown Nonwovens

- Applications: surgical masks (e.g. N95), industrial filtration, hygiene products

- Description: polymer melt blown into microfibres (0.5–5 μm)

Key properties:

- very low density

- extremely high porosity

- excellent filtration efficiency (dust, bacteria, viruses)

- high absorbency

- good flexibility

Chemically Bonded Nonwovens

- Applications: air filters, protective clothing

- Properties: flexibility, high strength, controlled filtration and mechanical parameters

Laminated Nonwovens

- Description: multi-layer structures bonded with adhesives or thermal lamination

- Properties: water and chemical resistance, enhanced durability

- Applications: protective clothing, surgical masks, roofing membranes, food packaging

We also design and manufacture nonwovens based on individual customer requirements.

Water-Absorbing Nonwovens (Composites) for Power Cables

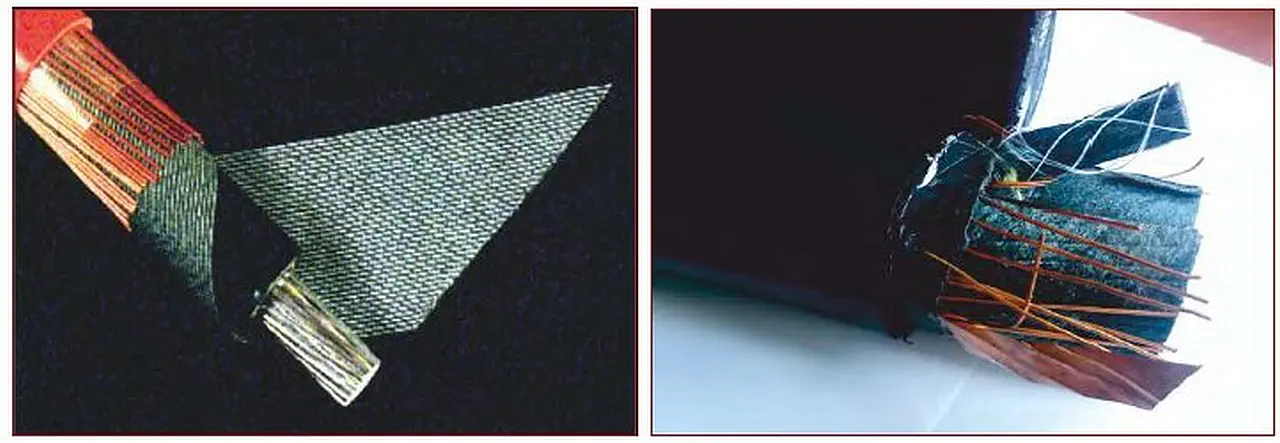

Water-absorbing (swelling) nonwovens play a key role in the production of power and telecommunications cables. Their function is to prevent longitudinal water penetration in the event of cable damage.

By instantly absorbing water and swelling, they block further water migration, protecting against short circuits, corrosion and moisture-related failures. These materials are resistant to oils, acids, bases and other chemicals commonly present in cable environments and offer high flexibility for various cable diameters.

Benefits:

- enhanced safety

- Increased reliability

- Extended service life

- Reduced maintenance costs

Cable Tapes

Water-Blocking Tapes

BLOK–WZTK – non-conductive tape

BLOK–WIWE – semi-conductive tape

Tape Categories:

- Water-blocking

- Semi-conductive (power cables)

- Flame-retardant (all cable types)

Technical parameters:

- Minimum tape width: 5 cm

- Maximum roll length: 1000 m

BLOK – WZTK – taśma nieprzewodząca

Waterproof tapes are designed to prevent water from entering fibre optic, copper, telecommunications and power cables. The use of the highest quality super-absorbent polymers (SAP) ensures excellent performance during the first minute of reaction to water. SAP is laminated and evenly distributed on various non-woven materials, thanks to which all SAPs effectively contribute to the water-blocking properties of the tape.

Key features:

- Proven long-term performance as a replacement for traditional filling gels in fibre optic cables

- does not provide a breeding ground for fungi

- high swelling rate

- thermally stable gel

- available in various swelling heights,

- available in lengths that optimise production efficiency

Semi-Conductive Tapes

- WOM E1 – stitched

- WIEP – carbon-loaded conductive

Semiconductor tapes perform electrical functions in cables. Their primary function is to equalise the field strength around the conductor or core and ensure electrical contact with the grounding system. This reduces electrical stress on the insulating material and increases efficiency. They can also be used to prevent electrolytic corrosion of metal armour layers. Tapes are an excellent solution for screening cores and wires. They prevent extruded wires from penetrating the strands, and thanks to their high tensile strength and abrasion resistance, they help prevent strand loosening thanks to their strong binding properties. All tapes are halogen- and sulphur-free, which improves fire safety and prevents copper staining.

Key features:

- High electrical conductivity

- Abrasion resistance

- Thermal stability

- ensures good contact with the wire or core

- high tensile strength and tear resistance, enabling rapid reaching and joining of cores

- good thermal stability resistant to overheating

- preventing punctures through insulation or extruded semiconductive layers

Services

Slitting and Rewinding (Bobbin Winding)

Cutting and rewinding of large rolls (tapes, nonwovens, paper, films, textiles) into smaller rolls for further processing or sale.

Applications of cutting and rewinding services on a bobbin winder:

- Nonwovens: Cutting and rewinding nonwovens (e.g. polypropylene, polyester) into smaller rolls that can be used to produce protective masks, workwear, filters, geotextiles and other industrial materials.

- Paper: Cutting large sheets of paper into smaller rolls, e.g. in the production of toilet paper, paper towels, napkins, etc.

- Films: Cutting and rewinding plastic films used in packaging, product protection and stretch film production.

- Textiles: Cutting and rewinding textile materials that will subsequently be used in clothing, upholstery, or other textile products.

Due to the specific nature and scope of the service provided, valuations are carried out on an individual basis.

Experimental production is an integral part of the activities of the Łódź Institute of Technology.

Thanks to our modern scientific, laboratory and technical facilities, we are able to produce almost any textile product tailored to the needs of even the most demanding customer.

Individual

individual approach to each customer

Professional

and a fully trained team of specialists

Many years

of experience in the market

Competitive

prices and a wide range of services

Our goods and services are used by international corporations as well as medium-sized and local companies involved in the construction, infrastructure, energy and laboratory sectors.

We give our products many individual features and properties depending on the intended use of a given product.

In our portfolio, you will find articles with the following properties, among others:

The Experimental Production Department manufactures specialised technical nonwovens. They are made from natural, synthetic and mixed fibres.

These nonwovens are designed for the following sectors:

- Energy

- Agriculture

- Automotive industry

- Construction

- Textile industry

- Medicine

Our nonwovens are neither woven nor knitted. The fibres are bonded mechanically, thermally or chemically.

The Experimental Production Department also fulfils individual orders – we give the nonwovens individual characteristics that are important to the customer.

We have a machine park that enables us to provide services such as cutting and rewinding.

We offer the use of Stoll ADF 530−16 ki BcW flat crochet machines with an E18/16 needle gauge. They enable the production of modern, row-knitted fabrics and tailored products for the clothing, medical, technical and other industries.

Mariusz Sawicki

Tel.: +48 504 140 332

e-mail: mariusz.sawicki@lit.lukasiewicz.gov.pl

Magdalena Czerwińska

Tel.: +48 518 390 964

e-mail: magdalena.czerwinska@lit.lukasiewicz.gov.pl

Ewelina Baranowicz

Tel.: +48 502-424-024

ewelina.baranowicz@lit.lukasiewicz.gov.pl

PhD Eng. Michał Chrzanowski

tel.: + 48 502 424 074

e-mail: michal.chrzanowski@lit.lukasiewicz.gov.pl

MSc Eng. Małgorzata Giełdowska

tel.: +48 600 450 128

e-mail: malgorzata.gieldowska@lit.lukasiewicz.gov.pl